|

| Contact Us |

| |

Add: Room 1204, Tiantong nan road 577-39#, Yinzhou District, Ningbo 315100, China

P.C: 315100

Tel: +86-574-88189478

+86-574-28870228

E-mail:nord@cnool.net

E-mail:admin@nord-foundry.com

|

|

|

|

|

Welcome

to Steel Casting |

|

|

| We are a China steel casting company, producing all kinds of steel casting parts, Alloy steel casting,Carbon steel steel casting,Stainless steel casting parts,Lost wax process steel casting parts.We are the leading China steel casting inc. The steel casting parts,In our China steel casting factory is in good quality. Our China steel casting co.,ltd use lost wax casting and sand process to produce steel casting parts,The materials of steel casting parts will be designed by our engineer in the China.But as a China steel casting Supplier, we can produce steel casting according to your requirements.Our China steel casting corporation have different sizes of steel casting parts,You can see some of steel casting parts, steel casting. We did in our China steel casting co.,ltd website! Our China steel casting company has emerged as one of the top innovators among China steel casting manufacturers. Our steel casting are exported to Canada, Holland, Australia, Spain and America! Our steel casting are wear-resisting,not fracture,greatly reducing replacement and improve working efficiency.

steel casting AG,steel casting GmbH,steel casting KG,steel casting Ets,steel casting SA,steel casting Cie,steel casting S.P.A,steel casting S.R.L.steel casting AB,steel casting HB,steel casting KB,steel casting AS,steel casting IS,steel casting AS,steel casting KS,steel casting AB,steel casting OY,steel casting CV,steel casting BV,steel casting NV,steel casting AO,steel casting Llc,steel casting Cia,

We have strict quality by the user consistent high praise. If you need steel casting, please feel to contact us. Nord steel casting corporation will provide you best price with high good quality!

Nord steel casting company in China,starting since 2001, is a Chinese steel casting company, specialized in manufacturing all kinds of carbon steel , alloy steel, stainless steel,ductile iron,grey iron,gray iron,High manganese steel,High chromium iron...casting parts, which are used in the field of transportation equipment(train parts/vessel parts), mining machinery, rubber machinery, some other heavy machineries,etc.

The reasons to choose us:1.Good Service.OEM and ODM service offered.1 year limited warranty for defective items(excluding items damaged and/or misused after receipt),2.Specialized steel casting Enterprise in China.Simulation of the casting system,Proficient in 3d design software,solidworks,Pro.CAD with rich experienced technical teams,Provide Complete Casting Solutions3.Quality Assurance.Well-equipped testing facilities,Good quality control system,4.Competitive Prices, First Choice.Save Cost Creating Values for You. |

|

|

|

|

| Process Description |

| Steel casting |

Steel casting is a specialized form of casting involving various types of steel. Steel castings are used when cast irons cannot deliver enough strength or shock resistance.

Examples of items that are steel castings include: hydroelectric turbine wheels, forging presses, gears, railroad truck frames, valve bodies, pump casings, mining machinery, Buckets Teeth ,Turbines ,engine casings and so on. |

| Steel Casting Process |

|

|

|

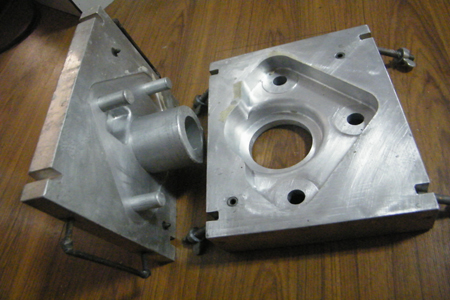

1. Mould Designing

Strictly making 3D model based on customer’s drawing dimensions, and mastered the contractibility rate for all types of material. |

2. Wax Injection

Wax design of the desired castings are produced by injection molding. These

designs are called patterns. |

|

|

3. Assembly

The patterns are attached to a central wax stick, called a sprue, to form a casting cluster or assembly. |

4. Shell Building

The shell is built by immersing the assembly in a liquid ceramic slurry and then into a bed of extremely fine sand. Up to eight layers may be applied in this manner. |

|

|

5. Dewax

At this point, all of the residual pattern and gating material is removed, and the ceramic mold remains. The mold is then preheated to a specific temperature and filled with molten metal, creating the metal casting |

6. Mould Shell Roast:

This process is to put the lost-wax shell into the roast furnace and make them harder. Heating the Mould shell before casting is also to ensure the better products surface texture. |

|

|

7. Smelting the Liquid Steel:

Allocate the chemical composition and sampling before steel casting. |

8.Spectrochemistry Analysis

Inspection on materials by spectrometer testing. |

|

|

9. Conventional Casting

In the conventional process, the shell is filled with molten metal by gravity pouring. |

10. Cut Off

The parts are cut away from the central sprue using a high speed friction saw. |

|

|

11.Heat Treating

Carbon steel and low-alloy steel need normalizing and temper, oil-quenching, water-quenching and so on. We can set out different heat treatment method as per different requirement from customers. |

12. Polishing

Polishing is to modify the out of flatness on casting head after casting cuttig and to modify the burring and splashings in the process of casting cycle. |

|

|

13. Inspection:

Inspection of the mechanical properties, surface, internal quality, and to check if the rough dimension meet the drawing requirement for the prodcuts. |

14. Machining

Cut the piece of raw material into a desired final shape and size. Now we have CNC, Lathe, milling machine, drilling machine, boring lathe and grinding machine. |

|

|

15.Quality Inspection:

Quality inspection on the machining dimension. Mainly tools we use is like specialized gauge and callipers, mircocalliper,three-dimensional and so on. |

16. Storage and Delivery

Efficiency of package goods delivery on time per your shipping requests. |

| Emphasis on quality control: |

|

1.The make of technology research recording card:

We can assure there will be no any holes, blister, crack, shrinkage cavity and so on based on technology. We will do some records about the easy-making mistake during the products development and note the correct operation methods.

2.Wax Mould sampling and Dimension inspection:

This process is to avoid changing of wax pattern contractibility rate results from the temperature change in the wax-pattern workshop, and finally result in products dimension disqualification. The rectification measure includes: Adjusts the temperature at the wax injection workshop and the water temperature used in Wax pattern cooling; testing tools; Callipers; Microcalliper;inner diameter gauge and Hight gauge.

3.Molten steel temperature control:

Investment casting differs from sand casting, Casting temperature need to be controlled perfectly, low temperature will result in incomplete products casting and have lack of body on the products;Excessive High-temperature will results in crack on the products. We install temperature inductor by the furnace and ask workers do temperature recording when casting, for the aim of better control the temperature.

4.Molten steel chemical composition control:

our company owns advanced Spectrograph imported from Germany to assure that the products chemical composition conformed with specified standards. We will also test the molten steel composition before products casting, simultaneously, molten steel after casting will be sampled for Spectrograph testing, guide sample after casting will be kept for 2 years and also can keep as per customer’s requirement.

5. Products heat treatment control:

Correct heat treatment process is the only way to assure the products mechanical properties. We will design the heat treatment technology as per the products chemical composition and mechanical properties standards and provide the heat treatment process reports and temperature recording reports according to customer’s requirements.Also we can provide customer products testing bar in the same heat treatment furnace for customer inspection.

6.Products surface quality and dimensional inspection:

We have passed ISO:9000 certificate, and own special quality inspection department. With different products, quality inspection department will design different fixture and gauge. We will do 100% inspection upon the products for quarantee unqualified products scrapped in our company. |

|

|

|

|

|