|

| Contact Us |

| |

Add: Room 1204, Tiantong nan road 577-39#, Yinzhou District, Ningbo 315100, China

P.C: 315100

Tel: +86-574-88189478

+86-574-28870228

E-mail:nord@cnool.net

E-mail:admin@nord-foundry.com

|

|

|

|

|

Welcome

to Truck Undercarriage |

|

|

| We are a China Truck Undercarriage company,producing all kinds of Truck Undercarriage parts,We are the leading factory In China

factory is in good quality.The materials of Truck Undercarriage will be decided by you or it will be equivalent in China.But

as a China Truck Undercarriage Supplier,we can produce Truck Undercarriage according to your requirements.We can do different sizes

of Truck Undercarriage parts,You can see some of Truck Undercarriage parts on our website. We export goods to America,Canada,England

(Britain,United Kingdom),France,Germany,Australia South Africa Holland,Spain market...! We also welding bucket Our bucket is

easy welded,not fracture,wear-resisting,greatly reducing replacement and improve working ding Fabrication corporation will

provide you best price with high good quality! Nord Truck Undercarriage

in China,starting since 2001,is a Chinese Truck Undercarriage company,specialized in manufacturing all kinds of Truck Undercarriage,

Caterpillar Truck Undercarriage,Komatsu Truck Undercarriage, Hitachi Truck Undercarriage,John deere Truck Undercarriage,Volvo steel

structure,JCB Steel Welding

Fabrication,Modern Truck Undercarriage,Daewoo Truck Undercarriage..., Domestic sales

estination:Shanghai,jiangsu,nanjing,wuxi,suzhou,zhejiang,hangzhou,ningbo,wenzhou,taizhou,jiaxing,shandong,beijing,

inan,qingdao,dalian,shenyang... The reasons to choose us: 1.Good Service.OEM and ODM service offered.1year limited warranty

for defective items(excluding items damaged and/or misused after receipt) 2.Specialized Casting Enterprise in China.Simulation

of the casting system,Proficient in 3d design software,solidworks ,Pro.CAD with rich experienced technical teams,Provide

Complete Casting Solutions 3.Quality Assurance.Well-equipped testing facilities,Good quality control system 4.Competitive

Prices,First Choice.Save Cost Creating Values for You. |

|

|

|

|

| Process Description |

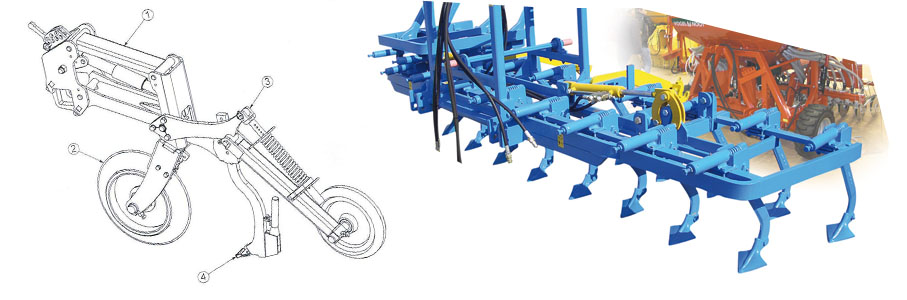

| Welding Fabrication parts,mainly used in agricultural machinery and exported to country with high agricultural automation,such as Canada,Australia,America etc. |

|

|

|

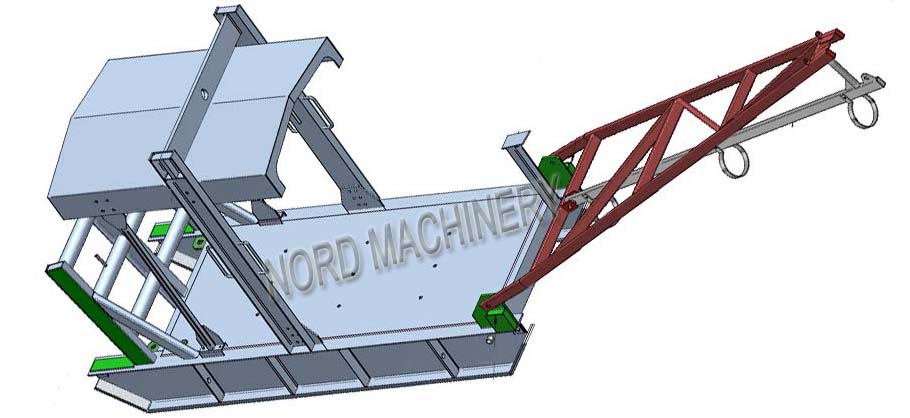

| The welding parts are mainly used in mining machinery,and our main exported market is Australia with abundant mineral resources,Canada,South Africa etc. |

|

| Process flowsheet

|

|

|

|

material preparation --Make process analysis and material and material preparatio

(steel sheet,section bar,welding flux and other accessory material) |

material cleaning --surface treatment(rust cleaning, oil and scale removal and so on ) |

|

|

|

|

material trimming --material cutting ,blanking,thermal cutting ,numerical control cutting abd so on |

material rolling --hot and cold forming machining(bending, stretching,rolling formation and so on) |

|

|

|

|

machining -Cut the piece of raw material into a desired final shape and size.

Now we have CNC, Lathe, milling machine, drilling machine and so on . |

welding excavator bucket --weld the assembled structure together to shape firmly together as a whole . |

|

|

|

balsting --this process can make the products surface color to be the same and remove the polishing trace. |

excavator bucket ,painting --coating(rust and scale removal ,pickling ,painting and so on and package. | |

|

|

|

|